Screw compressors – Kinds as well as applications

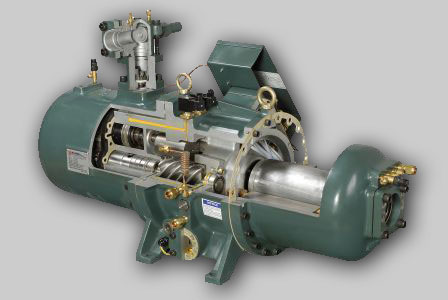

Screw compressors are particularly made to deal with a broad selection of completely dry material transfer ranging from granulates, concrete and plastics to sand, flour, lime as well as silicate. Its body contains two kinds of screws better known as the women and also male screws. Women screws are those with concave inlets while male screws have convex ones. Screw compressors run in other instructions. It is the women screw that receives the driving power. The male screw on the other hand, is accountable for transferring the power driven by the female variation. It passes through a collection of the so-called synchronization equipments. Aside from the major functions of male and women screws in a compressor, there are various other important parts of the procedure. While the screws begin rotating, the admission procedure occurs. This is where the air fills the inlet port consequently inhabiting the space between both screws.

Next to the admission stage is the compression phase. This is when the male thread stops or blocks the female string. During this stage, the rotation of the screws starts to reduce. When the quantity gets to the compressor’s distribution electrical outlet then the exhaust phase occurs. The exhaust stage is that circumstances when the screws not have contact with each various other. Total reliability is gotten during the treatment hence allowing the screw compressors to be of excellent use to several applications Common examples are hydraulic power systems, electrical motor and fixed and mobile applications. There is one type called the rotary screw compressor. This is found under the kinds of gas compressors. It makes use of a mechanism via a single screw or a double counter helical screw. While the system does its work, gas can be drawn via the casing’s port after that captured in a particular cavity. Discharge of the gas is then made to another port in the case. This type of Screw Compressor is applied generally markets such as those trailer devices powered by diesel as seen in building sites.

An additional particular kind is the oil-flooded screw compressor. This is often practical in securing and cooling gas costs. As the oil moves at the same time, it goes through separation from the discharge stream prior to it is cooled as well as filteringed system. In the future, the oil is recycled. Oil-free screw compressors are additionally instances of this industrial machinery. Without the visibility of any type of oil, air compression is made likely by the screws. This type is fairly essential in clinical looks into as well as in semiconductor industries.